Equipped with advanced technology and excellent engineering, our forklifts make it easier to work in tight spaces, increase the agility of our operators and allow for precise placement of loads. This feature is ideal for users working in confined spaces or busy warehouse environments, optimizing productivity by increasing in-warehouse mobility.

All our electric forklifts are equipped with the specially designed and developed “SafeTurn Mode”. This mode allows the forklift to automatically reduce speed when turning, allowing operators to maneuver more safely in tight spaces or busy warehouse environments. The slow-down feature on bends supports the operator in maintaining the balance of the load during the turn, while also aiming to maximize occupational safety standards.

Rabbit mode allows you to speed up your business processes in large and unmanned areas. You can use this mode when you want to move loads quickly and effectively or maneuver quickly in storage areas. This helps you increase productivity by speeding up your operations. Turtle mode is used in operations where pedestrians may also be on the forklift route or where pedestrians are worked closely with. At the same time, when working in narrow spaces or with valuable loads, thanks to this mode, operators can maneuver more carefully and carry loads more safely. This mode provides operators with a more controlled operation in sensitive jobs that require safety and control.

The hill support system allows you to work safely on sloped areas as well as on flat surfaces. When working on slopes, the Hill Support System is activated and prevents the forklift from rolling back. In this way, the operator can drive in a safer and more controlled manner on slopes.

The operator detection system, designed to ensure that the forklift operates in accordance with occupational safety and health rules, detects situations when the operator is not sitting in the forklift seat. In this case, the system automatically prevents the truck from moving and disables hydraulically operated features. These features help prevent occupational accidents by contributing to the safety of the operator and the maintenance of general safety standards in the workplace. In this way, it allows the forklift to be used only under appropriate and safe conditions, improving working conditions at the workplace and increasing operational efficiency.

It is an energy saving measure that is automatically activated if the operator is not on the vehicle for a certain period of time. This feature reduces the truck's energy consumption during an operator break or short stop, reducing overall operating costs. At the same time, when the operator consciously returns to work, the forklift is quickly activated, so that the workflow is not interrupted and operational efficiency is increased.

The warning light on the forklift is generally used for occupational safety and attention-grabbing purposes. The warning light is often used as a warning sign, helping to attract the attention of other employees in the area where the forklift is operating. Especially in noisy and busy work environments, the location of the forklift becomes better visible thanks to the warning lights. This can help prevent accidents. The blue warning light warns surrounding personnel and other equipment by illuminating a certain distance with a blue light in the area where the forklift is operating. In addition to improving safety in the workplace, this allows workers to be aware of a forklift approaching in advance.

Battery charge status, operating hours information and error codes on the digital display help to optimize maintenance processes, solve problems quickly and ensure long-lasting and safe operation of the forklift. These systems also allow business owners to better monitor and schedule maintenance, ensuring forklifts operate at maximum efficiency.

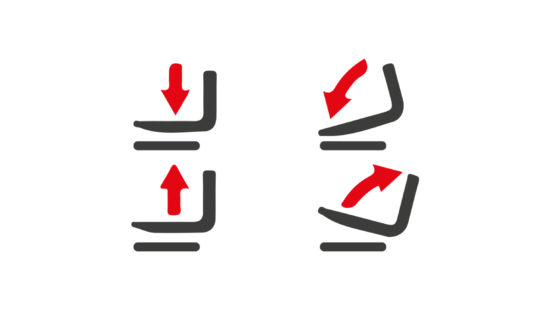

The “Integrated Side Shift” feature is a feature that provides the ability to move the load left and right in electric forklifts. This feature gives forklift operators greater maneuverability and flexibility, helping them move loads effectively in tight spaces.

Our electric forklifts are known not only for being environmentally friendly, but also for offering high-level performance in terms of operational safety. One of the cornerstones of this performance is the safe load lowering feature. While working with heavy loads, sudden oil leakage in hoses or connections may occur at speeds above the safe limit while lowering the load. There is a safety measure that is automatically activated in case of lowering attempt or accidental impact on the lowering arm.

The safe load carrying feature of the forklift is automatically activated when the transported load exceeds a certain lifting height. This feature instantly reduces the forklift speed slightly, preventing the load from exceeding specified limits. In this way, potentially dangerous situations such as the load and forklift tipping over are avoided. The system makes load handling operations more controlled and safe in order to increase the safety of the operator and his surroundings.

The “Full Free Lift” feature provides greater maneuverability and flexibility when working and retrieving materials in low-ceiling areas. It facilitates stacking in containers or trailers. The total height of the forklift does not change, up to 1.2 meters when the load stop is installed, and up to 1.6 meters when the load stop is not installed.

Designed by Göbbler Engineers, the elevator provides operators with a better view of their surroundings with its expanded viewing angle, which increases workplace safety. It helps operators have a better view and prevent accidents when maneuvering in tight spaces or placing materials in shelving systems.

It optimizes battery life by recovering the energy generated during braking, saves operating costs and reduces environmental impacts. At the same time, it contributes to occupational safety by increasing operator comfort. GÖBBLER combines its commitment to providing its customers with a sustainable and efficient material handling solution with its regenerative braking system.